In today’s competitive automotive industry, **vehicle assembling solutions** play a crucial role in helping global brands deliver high-quality, reliable, and innovative vehicles to market faster. From precision engineering to streamlined production lines, these solutions are the backbone of modern car manufacturing.

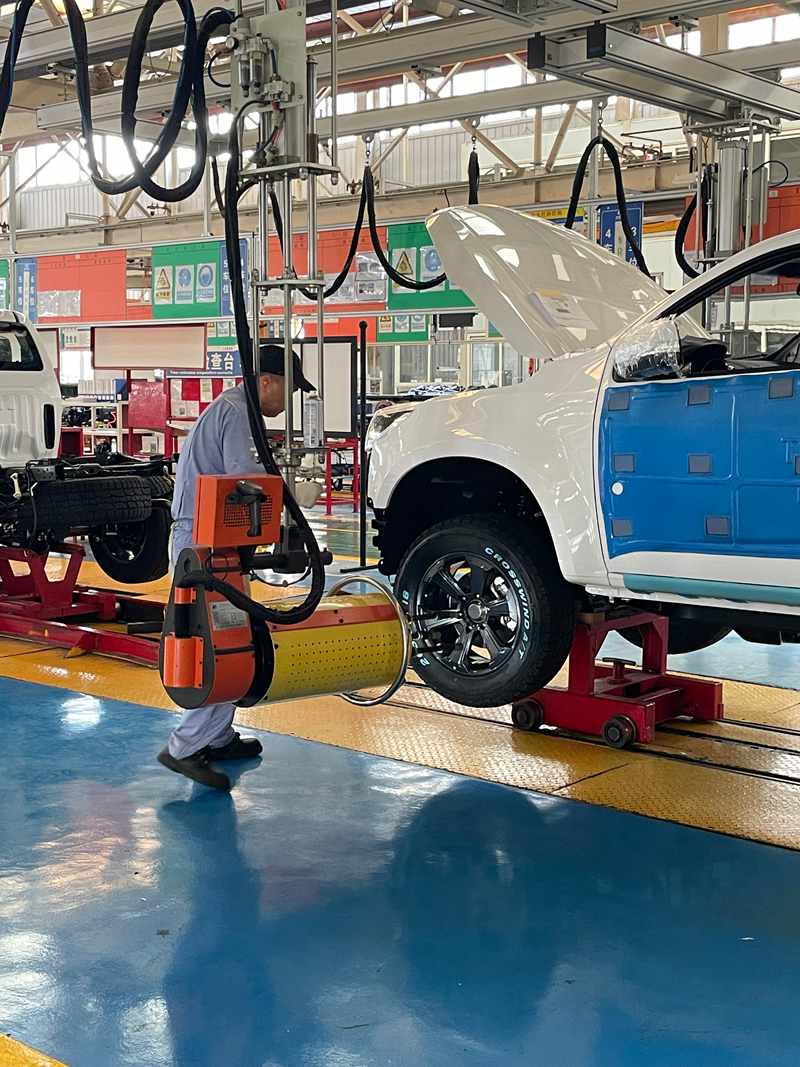

State-of-the-art assembly plants now combine advanced robotics, skilled labor, and smart technology to achieve unmatched precision and efficiency. Whether it’s passenger cars, commercial vehicles, or electric mobility solutions, tailored assembly processes ensure every model meets strict brand and safety standards.

Modern vehicle assembling relies on technologies like automated guided vehicles (AGVs), artificial intelligence (AI) quality control, and 3D printing for prototyping. These innovations reduce errors, optimize resource use, and enable faster model changes to meet shifting market demands.

For automotive brands with production facilities across multiple regions, scalability is key. Modular assembly systems allow seamless integration across plants, ensuring consistent quality and process efficiency while accommodating varying local regulations and market preferences.

Sustainability is no longer optional—it’s a necessity. Leading assembly providers incorporate eco-friendly manufacturing practices, such as energy-efficient machinery, waste recycling systems, and reduced carbon footprint logistics, to align with global environmental goals.

Every automotive brand has a unique identity, and assembly solutions can be customized to reflect that—from specialized trim installations to unique design elements. This flexibility ensures that vehicles not only meet technical specifications but also embody brand values.

Choosing the right vehicle assembly partner means gaining a competitive advantage. Experienced providers bring a combination of technical expertise, global logistics capabilities, and a commitment to quality that empowers automotive brands to focus on innovation and market expansion.